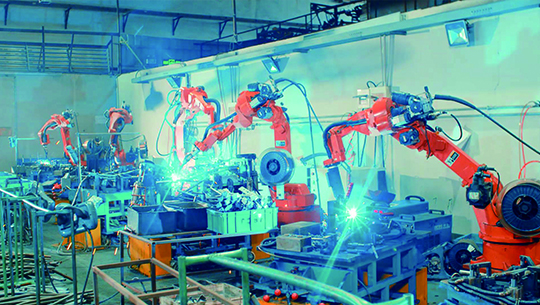

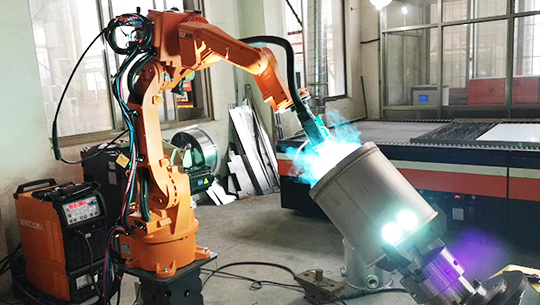

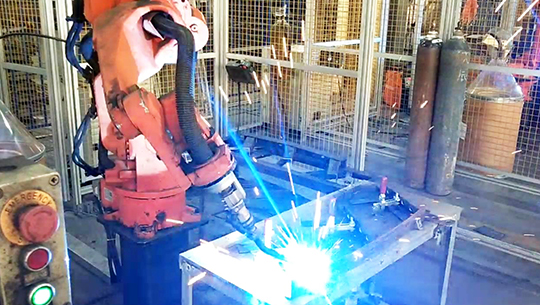

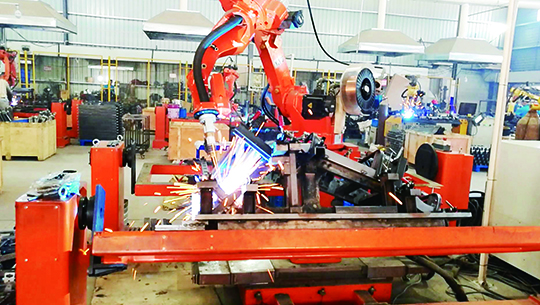

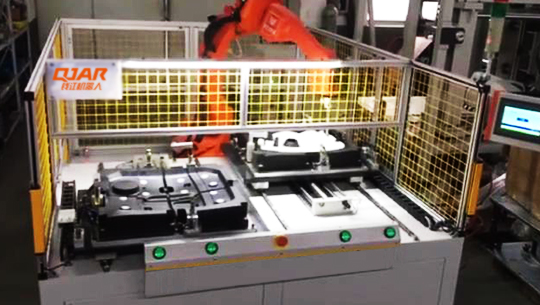

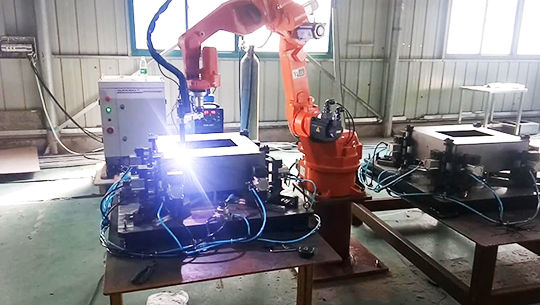

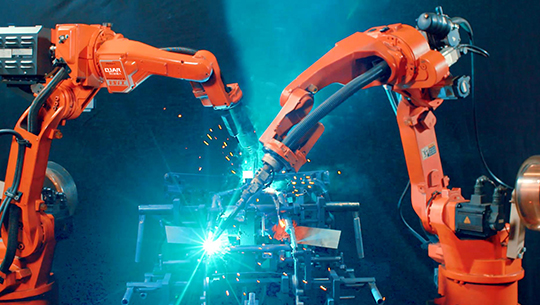

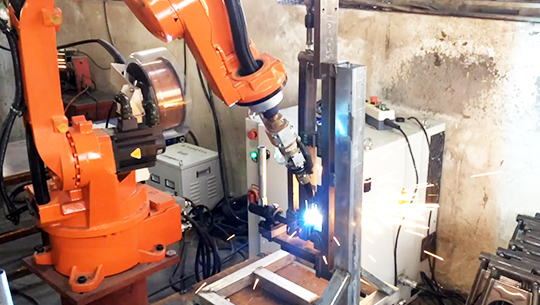

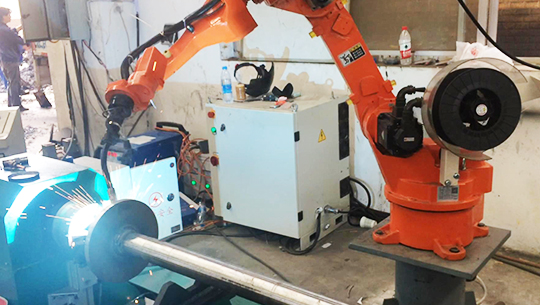

焊接制造工艺由于其工艺的复杂性、劳动强度、产品质量、批量等要求,使得焊接对于其工艺的自动化、机械化的要求极为迫

切,实现机器人自动焊接。弧焊接机器人能够准确地完成点各种直线、圆弧以及复杂曲线焊接作业,实现多种焊接工艺的自动化,

能够极大地提高零部件生产的自动化水平及生产效率,同时使得生产更具有柔性,焊接质量也得到了保证。

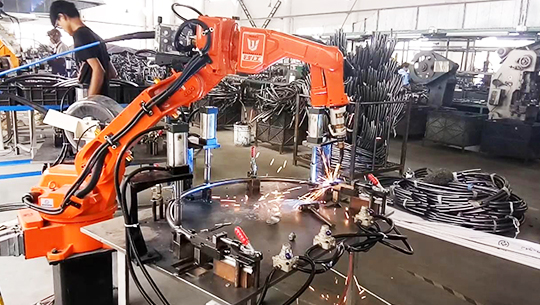

应用行业:汽车、汽车配件、摩托车、造船、机车车辆、锅炉、重型机械、铁路机车等制造行业。

产品优势:操作简单,能实现全自动焊接,效率高,无需人员操作,节省人力成本。焊接效果好,焊边平直均匀,性能稳定,无裂纹和气孔,硬度高且均匀。焊接发热小,高度一致,节省后续加工时间。

Due to the complexity of the process, labour intensive, product quality and high volume requirements, the automation of the welding process is one of the most pressing problems to be solved in the manufacturing industry. Arc welding robot can accurately complete all kinds of linear, curve and complex welding operation.The automated welding process can greatly improve the automation level, efficiency, flexibility, and quality of production lines.

Application Field: Automobile, auto parts, motorcycles, shipbuilding, rolling stock, boilers, heavy machinery, railway locomotives and other manufacturing industries.

Advantages: The advantages include simple operation, automatic welding, high efficiency, no welding operator, labor cost savings. The automated welding process provides flat and uniform welding seams, consistent results without cracks, pores, and having high and even hardness at the same time. The good welding quality reduces the requirement for post-process touch up.

型号:QJRH4-1A 应用行业:摩托车

型号:QJRH4-1A 应用行业:航空

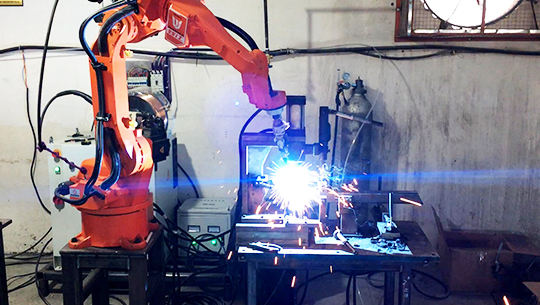

型号:QJR6-3 应用行业:工程机械

型号:QJRH4-1A 应用行业:特种设备

型号:QJRH4-1A 应用行业:健身器材

型号:QJRH4-1A 应用行业:汽车,汽摩配

型号:QJRH4-1A 应用行业:家电

型号:QJRH4-1A 应用行业:家电

型号:QJRH4-1A 应用行业:摩托车

型号:QJRH4-1A 应用行业:汽摩配

型号:QJRH4-1A 应用行业:特种设备

型号:QJRH4-1A 应用行业:玩具

型号:QJRH4-1A 应用行业:汽摩配

型号:QJRH4-1A 应用行业:汽摩配