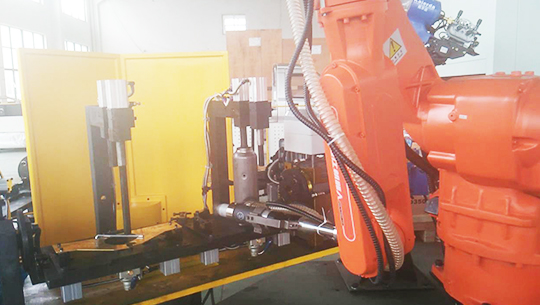

机器人抛光系统,利用工业机器人自动夹取工件,在砂带机上进行工件表面的自动化打磨抛光,产量高、质量稳定,抛光工位

隔离处理,全程无需人工接触作业,能有效实现金属粉尘的隔离和回收,改善工作环境,降低企业生产成本,杜绝了生产工人

吸入金属粉尘造成的身体危害,提高了生产安全性。

应用行业:金属、家电、汽车、摩托车、厨具等行业。

产品优势:快速装夹,示教简单,磨削质量高且一致性好,安全性高。

All kinds of metal casting products, such as bathroom faucets, door handles, automotive metal interior, etc.,

require surface polishing prior to electroplating and other follow-up processes. The traditional method is manual grinding, which requires high technical skills operators, long working hours, high labor intensity with a poor working environment that causes high frequent occupational diseases. The automatic polishing system

uses the industrial robot to automatically clamps the workpiece and perform surface polishing processes. This

provides high yield, stable quality, and able to effectively isolate and recover metal dust in order to improve

the working environment and reduce the production cost.

Application Field:Metal parts,home appliances,automotive,motorcycle and cookware.

Advantage:Quick clamping, simple teaching, combined with active constant force controller and articulated

arm teaching program, the system can be used by workers with no previous experience. The grinding quality

is high and the consistency is good. The active constant controller connected with the grinding tool can

maintain constant output that gives consistent surface quality.

型号:QJRB20-1 应用行业:五金

型号:QJRB20-1 应用行业:工程机械

型号:QJRB20-1 应用行业:工程机械